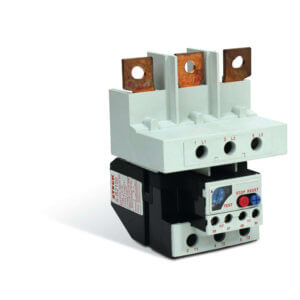

LC1D65AF7

LC1D65AF7 – TeSys D Contactor – 3P(3 NO) – AC-3 – <= 440 V 65 A – 110 V AC 50/60 Hz coil.

$225.00

| range |

TeSys

|

|

|---|---|---|

| product name |

TeSys D

|

|

| product or component type |

Contactor

|

|

| device short name |

LC1D

|

|

| contactor application |

Resistive load

Motor control |

|

| utilisation category |

AC-3

AC-4 AC-1 |

|

| poles description |

3P

|

|

| power pole contact composition |

3 NO

|

|

| [Ue] rated operational voltage |

Power circuit: <= 690 V AC 25…400 Hz

Power circuit: <= 300 V DC |

|

| [Ie] rated operational current |

80 A (at <60 °C) at <= 440 V AC AC-1 for power circuit

65 A (at <60 °C) at <= 440 V AC AC-3 for power circuit |

|

| motor power kW |

11 kW at 400 V AC 50/60 Hz (AC-4)

18.5 kW at 220…230 V AC 50/60 Hz (AC-3) 30 kW at 380…400 V AC 50/60 Hz (AC-3) 37 kW at 500 V AC 50/60 Hz (AC-3) 37 kW at 660…690 V AC 50/60 Hz (AC-3) |

|

| motor power HP (UL / CSA) |

40 hp at 460/480 V AC 50/60 Hz for 3 phases motors

5 hp at 115 V AC 50/60 Hz for 1 phase motors 10 hp at 230/240 V AC 50/60 Hz for 1 phase motors 20 hp at 200/208 V AC 50/60 Hz for 3 phases motors 20 hp at 230/240 V AC 50/60 Hz for 3 phases motors 50 hp at 575/600 V AC 50/60 Hz for 3 phases motors |

|

| control circuit type |

AC at 50/60 Hz

|

|

| [Uc] control circuit voltage |

110 V AC 50/60 Hz

|

|

| auxiliary contact composition |

1 NO + 1 NC

|

|

| [Uimp] rated impulse withstand voltage |

6 kV conforming to IEC 60947

|

|

| overvoltage category |

III

|

|

| [Ith] conventional free air thermal current |

10 A (at 60 °C) for signalling circuit

80 A (at 60 °C) for power circuit |

|

| Irms rated making capacity |

140 A AC for signalling circuit conforming to IEC 60947-5-1

250 A DC for signalling circuit conforming to IEC 60947-5-1 1000 A at 440 V for power circuit conforming to IEC 60947 |

|

| rated breaking capacity |

1000 A at 440 V for power circuit conforming to IEC 60947

|

|

| [Icw] rated short-time withstand current |

520 A 40 °C – 10 s for power circuit

900 A 40 °C – 1 s for power circuit 110 A 40 °C – 10 min for power circuit 260 A 40 °C – 1 min for power circuit 100 A – 1 s for signalling circuit 120 A – 500 ms for signalling circuit 140 A – 100 ms for signalling circuit |

|

| associated fuse rating |

10 A gG for signalling circuit conforming to IEC 60947-5-1

125 A gG at <= 690 V coordination type 1 for power circuit 125 A gG at <= 690 V coordination type 2 for power circuit |

|

| average impedance |

1.5 mOhm – Ith 80 A 50 Hz for power circuit

|

|

| [Ui] rated insulation voltage |

Power circuit: 600 V CSA certified

Power circuit: 600 V UL certified Signalling circuit: 690 V conforming to IEC 60947-1 Signalling circuit: 600 V CSA certified Signalling circuit: 600 V UL certified Power circuit: 690 V conforming to IEC 60947-4-1 |

|

| electrical durability |

1.4 Mcycles 80 A AC-1 at Ue <= 440 V

1.45 Mcycles 65 A AC-3 at Ue <= 440 V |

|

| power dissipation per pole |

9.6 W AC-1

6.3 W AC-3 |

|

| safety cover |

With

|

|

| mounting support |

Rail

Plate |

|

| standards |

CSA C22.2 No 14

EN 60947-4-1 EN 60947-5-1 IEC 60947-4-1 IEC 60947-5-1 UL 508 |

|

| product certifications |

CSA

GOST UL CCC |

|

| connections – terminals |

Control circuit: screw clamp terminals 2 cable(s) 1…2.5 mm²flexible with cable end

Control circuit: screw clamp terminals 1 cable(s) 1…4 mm²flexible without cable end Control circuit: screw clamp terminals 2 cable(s) 1…4 mm²flexible without cable end Control circuit: screw clamp terminals 1 cable(s) 1…4 mm²flexible with cable end Control circuit: screw clamp terminals 1 cable(s) 1…4 mm²solid without cable end Control circuit: screw clamp terminals 2 cable(s) 1…4 mm²solid without cable end Power circuit: screw connection 1 cable(s) 1…35 mm²flexible without cable end Power circuit: screw connection 2 cable(s) 1…25 mm²flexible without cable end Power circuit: screw connection 1 cable(s) 1…35 mm²flexible with cable end Power circuit: screw connection 2 cable(s) 1…25 mm²flexible with cable end Power circuit: screw connection 1 cable(s) 1…35 mm²solid without cable end Power circuit: screw connection 2 cable(s) 1…25 mm²solid without cable end |

|

| tightening torque |

Control circuit: 1.7 N.m – on screw clamp terminals – with screwdriver flat Ø 6 mm

Control circuit: 1.7 N.m – on screw clamp terminals – with screwdriver Philips No 2 Power circuit: 8 N.m – on EverLink BTR screw connectors – cable 25…35 mm² hexagonal screw head 4 mm Power circuit: 5 N.m – on EverLink BTR screw connectors – cable 1…25 mm² hexagonal screw head 4 mm |

|

| operating time |

4…19 ms opening

12…26 ms closing |

|

| safety reliability level |

B10d = 1369863 cycles contactor with nominal load conforming to EN/ISO 13849-1

B10d = 20000000 cycles contactor with mechanical load conforming to EN/ISO 13849-1 |

|

| mechanical durability |

6 Mcycles

|

|

| maximum operating rate |

3600 cyc/h 60 °C

|

| coil technology |

Without built-in suppressor module

|

|

|---|---|---|

| control circuit voltage limits |

Drop-out: 0.3…0.6 Uc AC 50/60 Hz (at 60 °C)

Operational: 0.8…1.1 Uc AC 50 Hz (at 60 °C) Operational: 0.85…1.1 Uc AC 60 Hz (at 60 °C) |

|

| inrush power in VA |

140 VA 60 Hz cos phi 0.75 (at 20 °C)

160 VA 50 Hz cos phi 0.75 (at 20 °C) |

|

| hold-in power consumption in VA |

13 VA 60 Hz cos phi 0.3 (at 20 °C)

15 VA 50 Hz cos phi 0.3 (at 20 °C) |

|

| heat dissipation |

4…5 W at 50/60 Hz

|

|

| auxiliary contacts type |

type mechanically linked 1 NO + 1 NC conforming to IEC 60947-5-1

type mirror contact 1 NC conforming to IEC 60947-4-1 |

|

| signalling circuit frequency |

25…400 Hz

|

|

| minimum switching current |

5 mA for signalling circuit

|

|

| minimum switching voltage |

17 V for signalling circuit

|

|

| non-overlap time |

1.5 ms on de-energisation between NC and NO contact

1.5 ms on energisation between NC and NO contact |

|

| insulation resistance |

> 10 MOhm for signalling circuit

|